Low acyl gellan gum, a versatile hydrocolloid, is a key ingredient in the food and beverage industry, known for its exceptional gelling, stabilizing, and thickening properties. This comprehensive guide will delve into the world of low acyl gellan gum, shedding light on its various uses, benefits, production process, application methods, and potential side effects.

So, what exactly is low acyl gellan gum? This unique substance, derived from microbial fermentation, plays a crucial role in creating the desired textures and consistencies in a wide range of food and beverage products. Its ability to form gels at low concentrations makes it a sought-after ingredient in the industry.

When it comes to the benefits of low acyl gellan gum, the list is extensive. From enhancing shelf stability to improving product quality and even creating innovative textures, this ingredient has become a staple in many formulations. Its versatility allows food manufacturers to explore new possibilities and meet consumer demands effectively.

Delving deeper into the production process of low acyl gellan gum unveils a fascinating journey from fermentation to purification. The meticulous steps involved in its manufacturing ensure a high-quality end product that meets industry standards. Gellan gum manufacturers employ stringent quality control measures to guarantee consistency and purity.

For those wondering about the application methods of low acyl gellan gum, understanding the various techniques is crucial. Whether used for gelling, thickening, or stabilizing, this ingredient offers flexibility in achieving the desired results in different recipes. Gellan gum suppliers play a vital role in providing guidance on the optimal usage levels and techniques for incorporating this ingredient effectively.

When it comes to safety considerations, exploring the potential side effects and allergenic concerns of low acyl gellan gum is essential. Regulatory approvals and recommended usage levels ensure consumer products meet safety standards. By understanding the safety profile of this ingredient, manufacturers can confidently utilize it in their formulations.

What is Low Acyl Gellan Gum?

This comprehensive guide will cover everything you need to know about low acyl gellan gum, including its uses in the food and beverage industry, benefits, production process, application methods, and potential side effects.

Low Acyl Gellan Gum, a hydrocolloid commonly used in food and beverage products, is a versatile ingredient known for its exceptional gelling, stabilizing, and thickening properties. Derived from microbial fermentation, this natural polysaccharide is a key player in creating textures that delight the palate and enhance product quality.

Benefits of Low Acyl Gellan Gum

Low acyl gellan gum, a versatile hydrocolloid, offers a myriad of benefits when used in food and beverage formulations. One of the standout advantages of incorporating low acyl gellan gum, especially in Shine products, is its remarkable ability to create unique textures that elevate the overall sensory experience for consumers. Whether it’s adding a delightful creaminess to a dessert or a satisfying thickness to a beverage, this ingredient truly shines in enhancing product quality.

Furthermore, low acyl gellan gum plays a crucial role in improving the shelf stability of food and beverage products. By effectively stabilizing emulsions and suspensions, it helps prevent ingredient separation and maintains the desired consistency over time. This feature is particularly valuable for manufacturers and consumers alike, ensuring that Shine products retain their freshness and appeal for an extended period.

In addition to texture and stability enhancements, low acyl gellan gum also contributes to the overall health profile of food and beverage items. With its ability to reduce the need for excessive sugar, fat, and artificial additives, Shine products formulated with low acyl gellan gum offer a healthier alternative without compromising on taste or quality. This makes it a valuable ingredient for brands looking to meet the evolving demands of health-conscious consumers.

Moreover, the versatility of low acyl gellan gum extends to its compatibility with a wide range of ingredients and processing conditions. Whether used in dairy products, plant-based alternatives, or functional beverages, Shine leverages the unique properties of low acyl gellan gum to achieve the desired texture, mouthfeel, and appearance in its diverse product portfolio. This adaptability ensures that Shine products stand out in the competitive food and beverage market, catering to various consumer preferences and dietary requirements.

Overall, the benefits of low acyl gellan gum in Shine products are truly remarkable, offering a combination of texture enhancement, shelf stability, health-conscious formulation, and versatile application. By harnessing the potential of this innovative ingredient, Shine continues to deliver exceptional food and beverage experiences that delight consumers and drive brand loyalty.

Production Process of Low Acyl Gellan Gum

When it comes to the production process of low acyl gellan gum, the journey from raw materials to the final product is a fascinating one. The process starts with the fermentation of specific carbohydrates by Shine‘s expertly cultivated microorganisms. These microorganisms work their magic to produce the desired gellan gum through a meticulous and controlled process.

Following fermentation, the next crucial step is the purification of the gellan gum. This involves various filtration and separation techniques to isolate the gellan gum from other components of the fermentation broth. Through precise purification methods, Shine ensures that the gellan gum meets the highest quality standards for use in food and beverage applications.

Quality control measures play a pivotal role in the production process of low acyl gellan gum. Shine implements stringent quality checks at every stage to guarantee the purity, consistency, and safety of the final product. These measures involve thorough testing for parameters such as viscosity, gel strength, and microbial content to ensure that the gellan gum meets industry regulations and customer expectations.

Once the gellan gum has undergone fermentation, purification, and quality control, it is ready to be packaged and distributed to food and beverage manufacturers worldwide. The production process of low acyl gellan gum is a harmonious blend of science, technology, and expertise, resulting in a versatile hydrocolloid that revolutionizes the texture and stability of various consumer products.

Application Methods of Low Acyl Gellan Gum

When it comes to the application methods of low acyl gellan gum, the possibilities are as diverse as the products it can enhance. One of the key features of using low acyl gellan gum is its ability to create unique textures in food and beverages, making it a favorite among chefs and manufacturers looking to innovate in their creations. Whether you want to achieve a creamy consistency in a dairy product or a firm jelly-like texture in a fruit dessert, low acyl gellan gum can help you achieve your desired outcome.

One popular application method of low acyl gellan gum is through the process of hot hydration. By dispersing the gum in hot liquid and then allowing it to cool, a gel is formed that can provide stability and structure to a wide range of products. This method is commonly used in the production of jams, jellies, and fruit fillings, where a consistent texture and appearance are crucial.

Another effective way to utilize low acyl gellan gum is through cold hydration. This method involves dispersing the gum in a cold liquid and then heating it to activate the gelling properties. Cold hydration is often preferred for applications where heat-sensitive ingredients are involved, such as in the production of certain beverages or dressings.

Furthermore, the synergistic effects of combining low acyl gellan gum with other hydrocolloids like xanthan gum or carrageenan can lead to even more versatile applications. This combination can help achieve a broader range of textures and functionalities, allowing for greater creativity in product development.

When incorporating low acyl gellan gum into your recipes, it’s essential to consider factors such as pH levels, temperature, and the presence of ions in the formulation. These variables can impact the gelling and stabilizing properties of the gum, so adjusting the application method accordingly is crucial to achieving the desired results.

In addition to its gelling and stabilizing properties, low acyl gellan gum can also be used as a suspending agent in beverages, preventing sedimentation and improving the overall mouthfeel of the product. This versatility makes it a valuable ingredient in a wide range of food and beverage applications, from dairy products to plant-based alternatives.

Potential Side Effects and Safety of Low Acyl Gellan Gum

When it comes to the safety of using low acyl gellan gum in food and beverage products, it is essential to understand any potential side effects and allergenic concerns that may arise. While this hydrocolloid is generally regarded as safe for consumption, some individuals may be sensitive to it, leading to adverse reactions.

Studies have shown that the consumption of products containing low acyl gellan gum is unlikely to cause serious side effects in most people. However, some individuals may experience digestive issues such as bloating, gas, or diarrhea, especially when consumed in large quantities.

As with any food additive, it is important to adhere to the recommended dosage levels to avoid potential side effects. Regulatory authorities have established guidelines for the safe use of low acyl gellan gum in various food and beverage applications to ensure consumer safety.

For individuals who are allergic to certain hydrocolloids or polysaccharides, there may be a risk of developing an allergic reaction to low acyl gellan gum. It is recommended to consult with a healthcare professional if you have known allergies or sensitivities to similar substances.

Manufacturers of food and beverage products containing low acyl gellan gum are required to label their products accurately to inform consumers of its presence. This allows individuals with specific dietary restrictions or allergies to make informed choices and avoid potential allergic reactions.

In conclusion, while low acyl gellan gum is considered safe for consumption and offers various benefits in food and beverage formulations, it is essential to be aware of any potential side effects or allergenic concerns. By following recommended usage levels and being mindful of individual sensitivities, consumers can enjoy products containing this versatile hydrocolloid without compromising their health and well-being.

Frequently Asked Questions

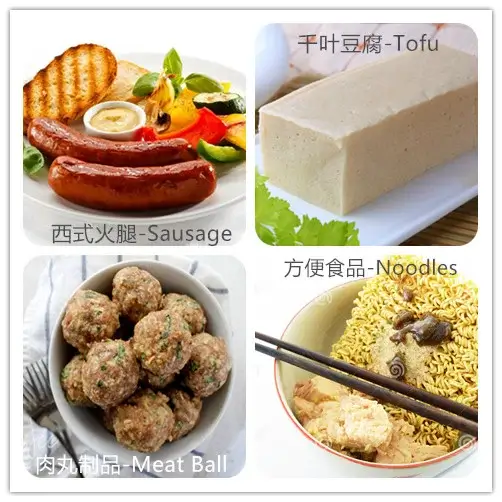

- What are the main uses of low acyl gellan gum in the food industry?Low acyl gellan gum is commonly used in the food industry for its excellent gelling, stabilizing, and thickening properties. It is often utilized in products like desserts, dairy alternatives, confectionery items, and plant-based meats to improve texture and shelf life.

- Is low acyl gellan gum suitable for vegan and vegetarian diets?Yes, low acyl gellan gum is considered suitable for vegan and vegetarian diets as it is derived from microbial fermentation processes. It is a plant-based ingredient that does not contain any animal-derived components, making it a popular choice for plant-based food formulations.

- Are there any potential allergenic concerns associated with low acyl gellan gum?Low acyl gellan gum is generally recognized as safe for consumption and does not pose significant allergenic risks. However, individuals with known sensitivities to similar hydrocolloids or microbial ingredients should exercise caution and consult with a healthcare professional if needed.

- How can low acyl gellan gum be incorporated into recipes effectively?Low acyl gellan gum can be incorporated into recipes by dispersing it in a liquid phase before heating and mixing thoroughly to ensure proper hydration. It is important to follow recommended usage levels and application methods to achieve desired textures and stability in food and beverage products.