Gellan Gum for Enhanced Dairy Milk Products

Milk Gellan Gum, plays an indispensable role in increasing the taste of dairy productsparticularly the HAM Type developed by SHINE additives, is making notable advancements in the dairy industry. It serves as an efficient stabilizing agent for milk and dairy beverages and acts as a thickening agent in dairy foods, offering unique benefits over traditional stabilizers like xanthan gum and carrageenan.

Unique Advantages in Dairy Applications

- Effective in a Wide pH Range: Especially suitable in acidic conditions, making it ideal for a variety of dairy products.

- Prevents Protein Sedimentation: When added to milk, it helps in preventing the sinking of proteins to the bottom during storage, maintaining consistent quality and texture.

Properties of HAM Type Milk Gellan Gum

- High Viscosity and Less Clarity: As a pure High Acyl Gellan Gum, it exhibits high viscosity in water after dissolving, but the solution is not as clear as that from Low Acyl Gellan Gum.

- Suitability in Milk/Dairy Products: Less sensitive to cations compared to low acyl variants and does not readily react with proteins, making it particularly suitable for milk and dairy products.

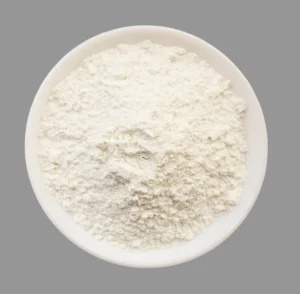

Recommended Dosage and Appearance

- Dosage: The recommended dosage for High Acyl Gellan Gum in dairy applications is between 0.025% and 0.035%.

- Appearance of Solution: In dairy applications, the Gellan Gum HAM solution typically appears milky or cloudy, which is particularly suitable for these products, adding to their rich and creamy texture.

- Setting Temperature: The setting temperature of around 50°C for Gellan Gum HAM is conducive to dairy processing, allowing for efficient integration into the production process without affecting the product’s quality.

Application Process

- Initial Mixing: Start by combining dairy milk Gellan Gum HA with 50% of the required water. This initial step is crucial for ensuring a homogenous blend.

- Dispersion: Vigorously stir the mixture to disperse the gellan gum evenly in cold water, avoiding lumps and ensuring a smooth consistency.

- Heating for Dissolution:Heat the mixture at 90°C for about 10 minutes. This step is essential for the complete dissolution of the dairy milk Gellan Gum, integrating it seamlessly into the liquid.

- Combining with Dairy: AAfter the dairy milk gellan gum is fully dissolved, incorporate it with 50% of pure soybean milk or any dairy milk. This combination is crucial for achieving the desired textural properties in the final product.

- Cooling: Finally, cool the mixture down to 25°C. This cooling process is vital for the gellan gum to set properly, ensuring the desired consistency and texture are achieved in the dairy product.

Expanding Applications in the Dairy Industry

The application of Milk Gellan Gum is not limited to traditional dairy products; it’s also being explored in innovative dairy alternatives, catering to the growing demand for plant-based options. This includes soy, almond, and oat milk, where Gellan Gum helps replicate the mouthfeel and consistency of animal-based milk.

The Future of Dairy with Gellan Gum

The use of dairy milk Gellan Gum, particularly in milk and dairy products, is a testament to the evolving nature of the dairy industry. As consumer preferences shift towards healthier and more sustainable options, Gellan Gum serves as a critical ingredient in meeting these demands. Its ability to enhance texture, maintain stability, and offer a versatile range of applications positions it as a key player in the future of dairy and dairy alternative products.

Sustainability and Health Benefits

In line with the industry’s move towards more sustainable practices, the use of dairy milk Gellan Gum in dairy products also aligns with environmental and health-conscious objectives. Its plant-based origin and production process contribute to a reduced ecological footprint, while

its natural composition aligns with the consumer preference for cleaner, healthier food ingredients.

Conclusion

In summary, Milk Gellan Gum, particularly the HAM Type from SHINE additives, is a transformative ingredient in the dairy industry. Its high viscosity, effectiveness across a wide pH range, and ability to prevent protein sedimentation make it a superior choice for enhancing dairy products. Its compatibility with various dairy and dairy alternative formulations further underscores its importance in modern food processing. As the dairy industry continues to evolve, Milk Gellan Gum stands as a pivotal ingredient, driving innovation and catering to the changing needs of consumers. It offers a sustainable and health-conscious alternative to traditional stabilizers, ensuring that dairy products not only taste great but also meet the highest standards of quality and nutrition.